Extruder machinery mechanisms where in substances or materials mechanically taken out to heating, collaborating, and cutting. These resulting in physical and chemical reforms for the duration of their path over and done with the extruder.

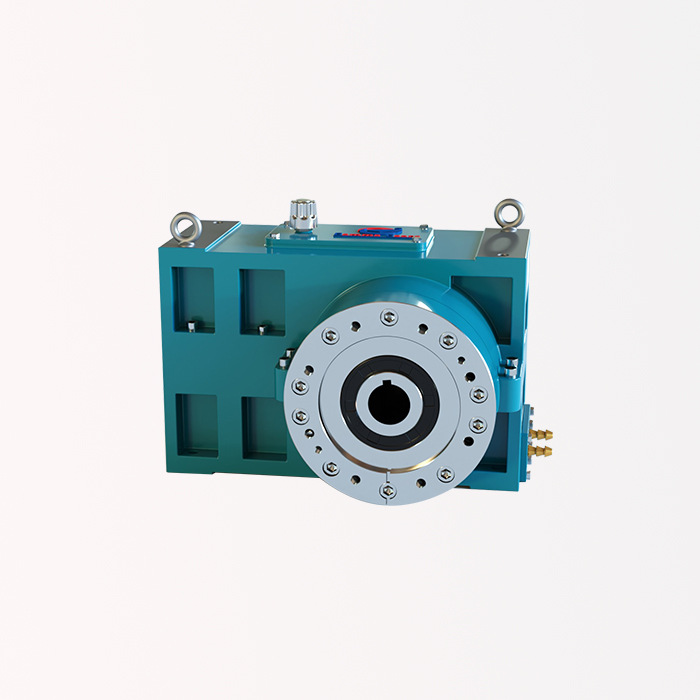

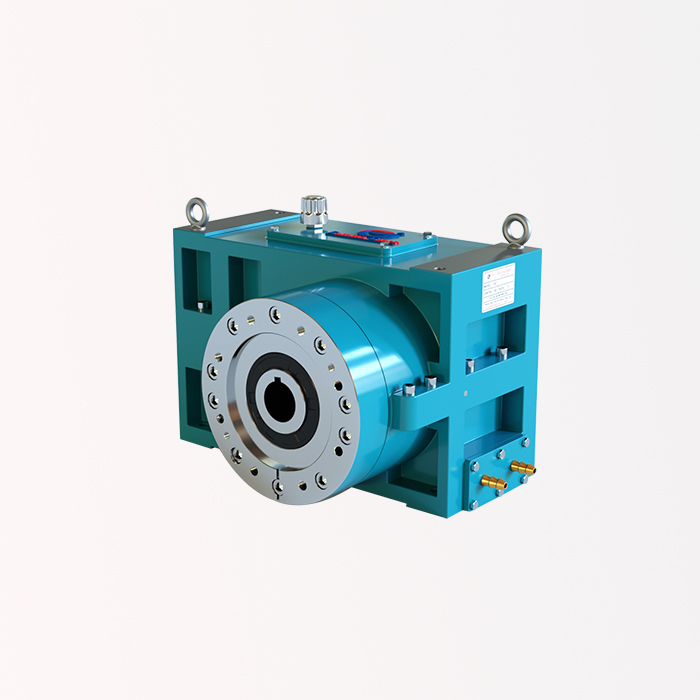

Extruder gear boxes for extruder mechanisms manufactured by Gamma Gears located in Ahmedabad make are fairly capable to transmit the extraordinary torque required for pressurizing and plasticizing moulding materials and also to absorb the high axial thrust load through built-in spherical roller thrust bearing. The axial comportment housing is standardized to accommodate suitable thrust bearings and corresponding output shafts with key are splined. The parallel shaft double reduction models ex-horizontal and vertical serve the distinguishing requirements of the extruder gearbox. To incorporate the thrust screw, different thrust bearings with different bores are mounted on the output shafts or hollow. The segmental design permits the interchangeability of the parts.

In Ahmedabad, Gujarat, India Gamma Gears as an excellent quality extruder gearbox manufacturer develop compact gear boxes capable of transferring high torques via shafts that have relatively small cross sections. They can also tolerate incredibly high axial forces thanks to an optimum arrangement of the tandem bearings. Having core business as a manufacturer in Ahmedabad, Gamma Gears assortment also contains in-house solutions for shaft extruders and kneading machines.

Gamma Gears Being as a foremost manufacturer in Ahmedabad, Gujarat, India, and our extruder gearboxes includes hardened and ground gears which are obtainable in double reduction, horizontal and parallel shafts models are generally designed to fulfill the precise necessities and condition that is normally happens with screw extrusion process.

The same gear boxes for extruder machinery mechanisms are have extraordinarily higher capability to transmit the high torque that is essential for pressuring and plasticizing molding materials and can be also used to absorb the high axial thrust loads by the support of its integral spherical roller thrust bearing. The axial bearing housing attached with the main case is reliable to contain suitable thrust bearing and corresponding output shafts.

All gear teeth are constructed with appropriate profile correction in accordance with the most modern method by utilizing computer assistant techniques to develop greater transmission productivity and capability. These gears are treated with heat by enclosing in modern sealed satisfied furnaces. You may get more details from Gamma Gears in Ahmedabad, Gujarat, India.

Gamma Gears supply the range which are factory-made consuming high-grade raw material obtained and with cutting-edge technology. Because of the features of these gearboxes products are largely much-admired for their satisfactory finish, stability, high workable power and erosion resistance.

Industrial demand for plastic, rubber and other machineries and supplies in industrial and customer applications is rising quickly, and in all physical states. As requirements are growing, novel machinery manufacturers and their end-user clienteles are on the lookout for new ways to progress the productivity of extruder machinery mechanisms and gearboxes.

Gamma Gears is the excellent extruder duty helical gearboxes manufacturers serving the extensive varieties of industries in India. Best results oriented, satisfied working and easy operation are some of the main features of the extruder duty helical gearboxes we supply. All these products are precision-engineered and manufactured utilizing the cutting-edge technological expansion and classy machines and tools.

In Ahmedabad, Gujarat, India, We have been effective as the extruder duty helical gearboxes suppliers as we are experts as a manufacturer for industry-specific gearboxes that are suitable for several purposes. Are you in search of low noise, highly efficient and high-performance gearboxes of all types? We are manufacturing and will be supplying to you gearboxes of multiple sorts exactly in line with your requirements.

Gamma Gears – the best extruder gearbox manufacturers is well-equipped with sufficient organization and a well knowledgeable team of engineers. We ensure the delivery of extruder gearbox for extruder machinery mechanism engineering processes on time, accurately according to your needs. We are specialized in making gearboxes of various types.

Tell us your demands and requirements. In Ahmedabad, Gujarat, India We are matching all your requirements with the required quality. As the best industrial gearbox suppliers, we serve to diverse industries and more.

High torque transmission: Extruder gear boxes are designed in such a way to handle high torque loads, permitting for the extrusion of resources with high viscosity or confrontation. This confirms proficient material handling and product value.

Stability and reliability: Extruder gear boxes are built to endure the demanding settings of extrusion processes, comprising high temperatures and high torque loads. They are developed for long service life and nominal maintenance.

Multipurpose industrial engineering applications: Extruder gear boxes are used in an extensive range of extrusion processes, together with plastic extrusion, rubber extrusion, and food extrusion. They can be modified to accommodate diverse materials and extrusion machinery procedures necessities.

Accurate control and constant output: The gear reduction and torque multiplication delivered by the extruder gear box allow for precise control over the extrusion progression. This outcomes in reliable product dimensions, exterior finish, and overall quality.

The best Extruder Duty Helical Gearbox with Universal Mounting manufacturers, Gamma Gears gearbox. Gamma Gears is very well-equipped with more sufficient set-up and an experienced team of Extruder Duty Helical Gearbox with Universal Mounting manufacturing high-qualified engineers. Gamma Gears assurance on-time delivery of Extruder Duty Helical Gearbox with Universal Mounting that meet your specifications. We are specialized in the manufacturing of Extruder Duty Helical Gearbox with Universal Mounting type gearboxes.

WhatsApp us